What Is a Steel Purlin?

A steel purlin is a horizontal structural beam used in steel construction to support roof and wall panels. They help distribute loads, prevent sagging, and provide resistance against wind, snow, and other external forces. Installed perpendicular to main rafters or beams, purlins are critical for the stability and safety of large-span metal roofs.

Why Use Steel Purlins in Construction?

Steel purlins are often referred to as the “backbone of the roof.” They provide more than just support:

Even Load Distribution – Spread roof weight evenly across the structure.

Enhanced Stability – Act as a skeleton for the roof, improving durability.

Cost Savings – Optimize steel usage and reduce material costs.

Fast Installation – Prefabricated design makes them quick to install.

Types of Steel Purlins

Steel purlins are categorized by cross-sectional shape. The two most common are:

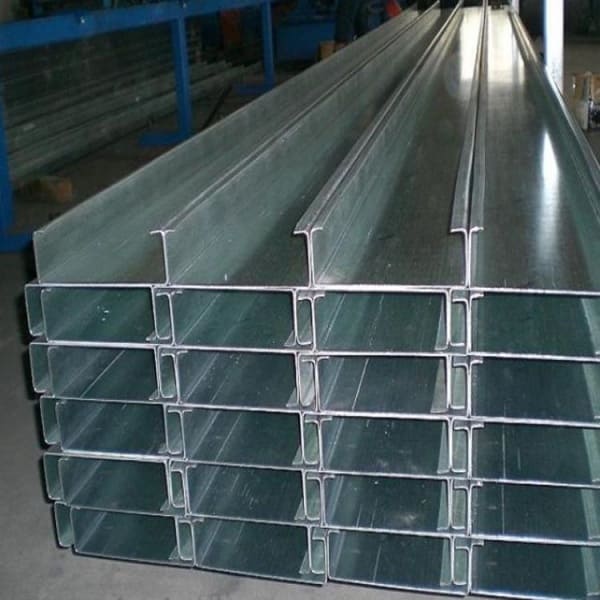

C-Purlins

Best for small to medium roofs

Simple installation

Limited for long spans

Z-Purlins

Best for large-span roofs & high-wind areas

Overlapping connections create stronger joints

Superior load distribution

Comparison Table: C-Purlins vs Z-Purlins

| Feature | C-Purlins | Z-Purlins |

|---|---|---|

| Strength | Good bending resistance | Superior strength for wide spans |

| Applications | Small & medium roofs | Large-span, high-load projects |

| Installation | Simple, non-overlapping | Overlapping, stronger joints |

| Cost | Lower, economical | Slightly higher but cost-efficient |

| Wind Resistance | Standard | Excellent |

Common Sizes of Steel Purlins

Steel purlins are available in different sizes depending on the project:

| Dimension | Typical Range | Application Example |

|---|---|---|

| Height | 100 mm – 300 mm | Small shops to large factories |

| Width | 38 mm – 100 mm | Light to medium projects |

| Thickness | 1.5 mm – 2.7 mm | Residential to heavy-duty use |

Spacing and Span of Steel Purlins

Purlin Spacing – Distance between adjacent purlins; smaller spacing = stronger stability.

Purlin Span – Length a purlin covers between supports; affects thickness and size requirements.

Common Structural Layouts

Single-Span – Simple, short-span projects.

Continuous-Span – Large roofs, efficient load distribution.

Overlapping Layout – Z-purlins for stronger joints.

Cantilever & Double-Span – For extended or complex designs.

Curved Layout – Used in stadiums or special designs.

Connection Methods for Steel Purlins

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Bolted | Easy, stable, removable | May loosen under heavy loads | Warehouses |

| Welded | Strong, permanent, wind-resistant | Requires skilled welding | High-load projects |

| Clip | Quick, simple, adjustable | Limited load capacity | Light structures |

7 Key Advantages of Steel Purlins

High strength & durability

Lightweight & easy to install

Versatile for all building types

Excellent fire resistance

Cost efficiency & long service life

Corrosion resistance in harsh environments

100% recyclable & eco-friendly

Partner With Us for Your Next Project

With 20+ years of experience and 1,000+ projects worldwide, we provide:

One-stop service from design to delivery

Certified ISO & CE steel products

Custom solutions for your project needs

Free consultation and quotation

👉 Contact us today to secure your next successful project.