Did you know the right building materials can cut energy costs by up to 30%? In modern construction, efficiency, durability, and sustainability are essential. That’s where sandwich panels come in.

These innovative components are now a cornerstone of steel buildings, offering strength, insulation, and design flexibility. But what exactly are sandwich panels, and how can they benefit your next steel building project?

This guide covers:

- What sandwich panels are and how they work

- Their benefits for steel construction

- Core materials and performance metrics

- Applications across different building types

- Installation, maintenance, and customization options

📌 Key Takeaways

- Sandwich panels make steel buildings more energy-efficient, durable, and flexible.

- Suitable for walls, roofs, ceilings, partitions, and cold storage.

- Core options include PUR/PIR, mineral wool, and EPS, each with unique advantages.

- Widely used in industrial, commercial, agricultural, and specialized facilities.

What Are Sandwich Panels?

At their core, sandwich panels are made of three layers:

- Two Outer Skins – usually galvanized or coated steel, sometimes aluminum, providing strength and weather resistance.

- Insulating Core – PUR/PIR, mineral wool, or EPS, enhancing thermal and acoustic performance.

- Bonded Structure – creating a lightweight yet durable system ideal for steel frameworks.

This design makes them lightweight, easy to install, and energy-efficient—a perfect match for steel structures.

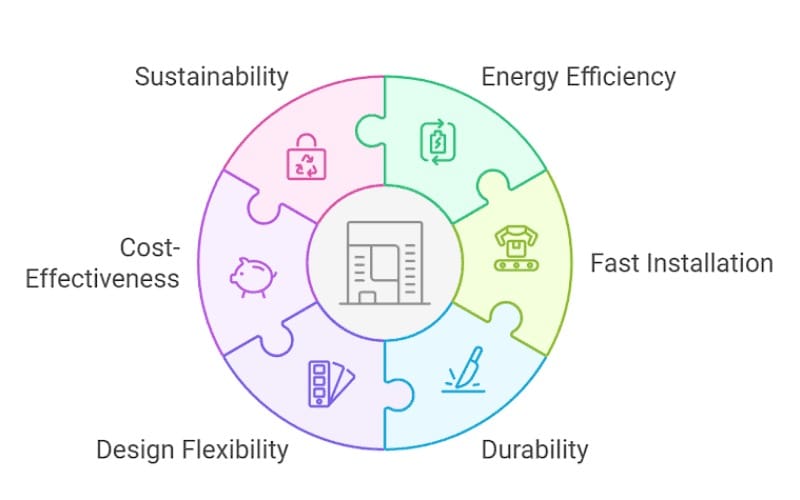

How Sandwich Panels Enhance Steel Buildings

- Energy Efficiency – Reduce heat transfer and cut HVAC costs.

- Fast Installation – Prefabricated panels save time on-site.

- Durability – Resistant to corrosion, weathering, and impact.

- Design Flexibility – Wide range of colors, finishes, and profiles.

- Cost-Effectiveness – Save on both construction and long-term operation.

- Sustainability – Insulation lowers energy demand; metals are recyclable.

Where Sandwich Panels Fit in Steel Buildings

| Application | Benefits | Ideal For |

|---|---|---|

| Walls | Excellent insulation, sleek finish | Offices, warehouses, factories |

| Roofs | Lightweight, waterproof, thermal efficiency | Industrial and commercial buildings |

| Ceilings | Smooth look, soundproofing, hides wiring | Schools, hospitals, offices |

| Partitions | Quick install, flexible layouts | Industrial facilities, commercial spaces |

| Cold Storage | High insulation, consistent low temperature | Food processing, refrigerated warehouses |

| Special Areas | Fire/moisture resistance, durability | Labs, clean rooms, explosion-proof spaces |

Choosing the Right Core Material

| Core Material | Key Benefits | Best For |

|---|---|---|

| PUR / PIR | Excellent thermal insulation, fire & moisture resistance | Energy-efficient steel buildings |

| Mineral Wool | Superior fire safety, soundproofing, eco-friendly | Safety-focused projects |

| EPS | Cost-effective, good insulation | Budget-conscious projects |

Performance Metrics of Sandwich Panels

- Thermal Conductivity (U-value): 0.20–0.50 W/m²K → consistent energy efficiency

- Fire Resistance: A2 or B1 depending on core → safer environments

- Acoustic Performance: Up to 40 dB reduction → quieter interiors

Installation & Maintenance

- Installation: Lightweight, prefabricated, easily mounted with fasteners or adhesives.

- Maintenance: Low-maintenance; simple cleaning with water and mild detergent keeps panels in top condition.

Customization Options

- Colors & Finishes: Metallic, corporate tones, textured surfaces

- Special Features: Anti-static (labs), antimicrobial (healthcare), solar-integrated (green roofs)

Common Dimensions

| Measurement | Typical Range |

|---|---|

| Thickness | 40–200 mm (thicker panels for cold storage) |

| Width | Standard ~1000 mm (custom available) |

| Length | Up to 12 m (custom available) |

Applications Across Steel Buildings

| Building Type | Applications | Benefits |

|---|---|---|

| Industrial | Warehouses, factories | Insulation, durability, quick build |

| Commercial | Offices, retail, supermarkets | Energy-efficient, aesthetic appeal |

| Cold Storage | Food plants, refrigerated warehouses | Maintains low temperatures consistently |

| Agricultural | Barns, sheds, livestock housing | Hygienic, insulated, low maintenance |

| Sports & Recreation | Gyms, arenas, centers | Lightweight, thermally efficient |

| Aviation/Transport | Airports, hangars, terminals | Withstands harsh environments |

| Healthcare | Hospitals, labs, clean rooms | Fire-resistant, hygienic, moisture-proof |

Final Thoughts

Sandwich panels are more than just cladding—they’re an essential system for steel buildings. From energy savings and faster installation to aesthetic flexibility and sustainability, they elevate every project.

Whether you’re planning a warehouse, office, or cold storage facility, sandwich panels provide the strength, performance, and efficiency your steel building needs.

📞 Need help choosing the right panels or planning your project? Contact our team today—we provide complete steel building solutions from design to delivery.

❓ Frequently Asked Questions (FAQ)

1. How long do sandwich panels last in steel buildings?

Sandwich panels typically last 25–40 years depending on the core material, coating, and maintenance. With proper care, they can perform even longer.

2. Are sandwich panels fireproof?

Not all panels are fireproof, but mineral wool cores provide the highest fire resistance (up to A2 rating). PUR/PIR cores also offer good fire safety when specified correctly.

3. What is the best sandwich panel for cold storage?

For cold storage and refrigeration, thicker PUR/PIR panels (120–200mm) are ideal because of their low thermal conductivity and excellent insulation.

4. Can sandwich panels be customized for design?

Yes. Panels are available in different colors, finishes, and textures, and can be tailored with special features like antimicrobial coatings or integrated solar panels.

5. Are sandwich panels environmentally friendly?

Yes. Sandwich panels help lower energy consumption and reduce carbon emissions. Both steel skins and some core materials (like mineral wool) are recyclable.

6. How do you maintain sandwich panels?

Maintenance is simple—regular cleaning with water and mild detergent is enough. Annual inspections for joints and fasteners help ensure long-term performance.