Expandable container homes may look compact from the outside, yet their internal structure is a masterpiece of engineering. Each unit is designed for strength, flexibility, and long-term performance. To understand why these homes can fold, transport, and expand safely, it helps to look deeper into their frame, materials, and sealing systems.

In this article, we’ll explore the main structural components that make these modern modular homes both durable and easy to deploy.

Steel Frame – The Structural Backbone

At the heart of every expandable container house lies a high-strength steel frame. Most manufacturers use galvanized or cold-rolled steel to prevent rust and enhance load capacity. The frame serves as both the skeleton and the anchor point for expansion mechanisms such as hinges, latches, and lifting joints.

Each corner post and crossbeam is precision-welded to bear heavy loads during transport and installation. The frame also ensures that when the unit expands, every wall aligns perfectly, keeping the structure square and stable.

Tip: Choose suppliers who provide structural drawings and test reports showing load-bearing strength — an important factor for long-term safety.

🔗 Learn more about expansion mechanisms in our Hydraulic and Manual Expansion Systems Guide.

Wall Panels – Strength with Thermal Comfort

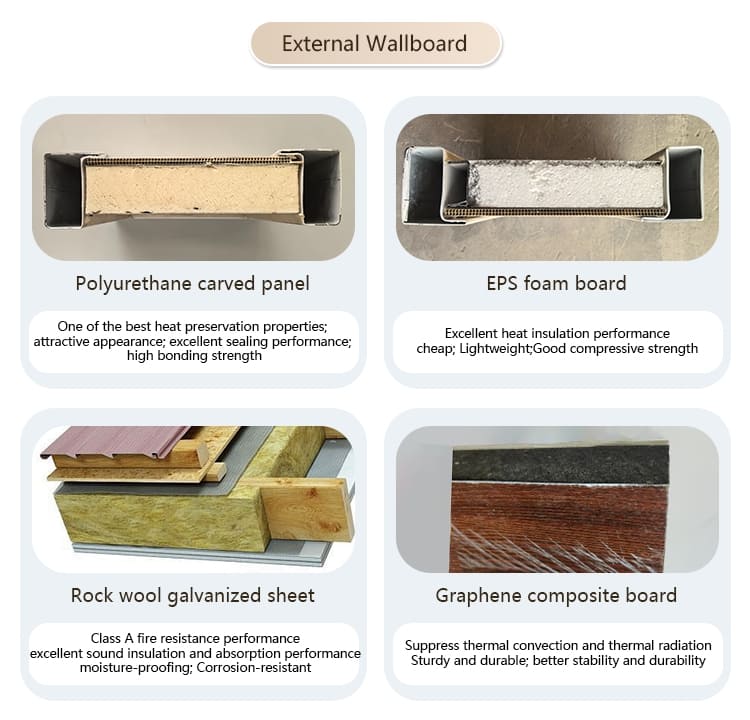

Expandable container houses typically use sandwich panels for walls — a composite of two steel sheets with insulation foam (like polyurethane or rock wool) in between. This combination keeps the house lightweight, weatherproof, and thermally efficient.

The panel design also allows quick assembly: once unfolded, each wall locks into the main frame through pre-mounted hinges and bolts. The tight joint design minimizes heat loss while providing excellent acoustic insulation.

Different panel thicknesses (50–100mm) are available depending on the climate. For cold regions, thicker panels with better R-values ensure comfortable indoor temperatures.

Floor and Roof Systems

The floor structure is another critical part. It usually consists of a steel joist frame covered with waterproof plywood or fiber cement boards. Some manufacturers also add vinyl or laminate flooring for interior comfort.

The roof system is made to resist rain and snow loads. Overlapping roof sheets, drainage channels, and sealing gaskets prevent water leakage. In some models, the roof can be lifted (roof-lift type) to increase headroom.

Hinges, Latches, and Sealing Details

The magic of expansion lies in the hardware details. Heavy-duty hinges connect the foldable walls, while stainless-steel latches lock them securely when expanded. Rubber compression seals run along each joint, ensuring waterproof and wind-resistant performance.

Well-designed seals mean no extra caulking is needed for side walls, only at the roof joints. This precision engineering prevents leaks and improves air tightness — key to comfort and durability.

Internal Systems Integration

Expandable homes are not just shells — they include wiring, plumbing, and insulation pre-installed within the panels. Electrical conduits and water lines are embedded during factory production, saving installation time on-site.

Some models also offer integrated LED lighting, sockets, and drainage systems. This factory-level precision ensures each connection remains safe even after multiple fold/unfold cycles.

Conclusion

The structure of an expandable container home reflects smart modular design — a balance of strength, flexibility, and comfort. From the reinforced steel frame to insulated sandwich panels and waterproof seals, every element is engineered for long-lasting performance.

Understanding this structure helps buyers choose quality units and suppliers with confidence — ensuring that your foldable home stays safe, durable, and energy-efficient for years.