Building and transporting a capsule house is an exciting project—but it requires precision and planning. From designing modules to managing permits and delivery, every stage matters. In this guide, we’ll explore the main challenges and offer expert solutions for a smooth experience.

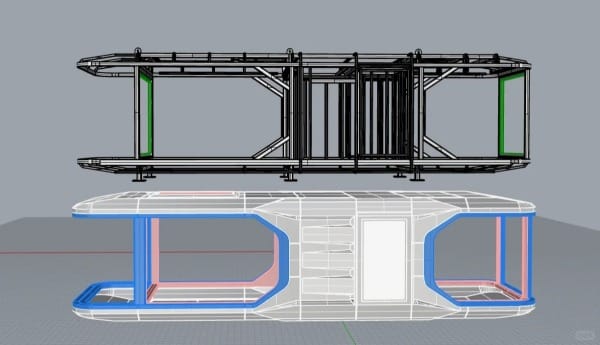

Design and Fabrication

Design accuracy is the foundation of a successful capsule house. Each prefabricated module must fit perfectly into the full layout.

Precise Dimensions:

Even small measurement errors can cause assembly issues. Using laser tools and computer-aided design (CAD) ensures exact sizing and error-free production.Site Adaptation:

Because land isn’t always flat, capsule houses are designed to allow minor on-site adjustments, helping them sit securely on uneven ground.Material Selection:

Lightweight steel frames and insulated panels are ideal. Steel adds strength, while insulated panels maintain comfort and energy efficiency in all climates.

Permits and Documentation

Before installation, ensure you have all required building permits. In Australia, projects must comply with the National Construction Code (NCC) for safety and energy standards.

If importing modules, prepare essential documents such as:

Bill of Lading and Commercial Invoice for customs

Packing List and Import Declaration for the Australian Border Force

Quarantine Certificate if wooden materials are used

👉 Austrade reports that over 70% of Australia’s prefab homes are imported from China—so paperwork accuracy is crucial.

Transportation and Logistics

Transporting a capsule house is not as easy as “load and go.” Oversized modules need route planning and special load permits.

Conduct a route survey to ensure roads, bridges, and turns can handle the module’s dimensions.

Secure the house with strong harnesses and shock-absorbing pads to avoid scratches or swings.

Use weatherproof and UV-resistant covers to protect during long trips.

| Capsule Size | Typical Dimensions | Best Container |

|---|---|---|

| Small (Studio) | 6m × 2.5m × 2.5m | 20ft Container |

| Medium (1BR) | 9m × 3m × 3m | 40ft High Cube |

| Large (2–3BR) | 12m × 3.5m × 3.2m | Flat Rack |

Site Preparation and Foundations

Before assembly, the ground must be cleared, leveled, and compacted.

Choose the right foundation depending on the soil and environment:

| Foundation Type | Description | Ideal Use |

|---|---|---|

| Steel Legs | Adjustable screw-in supports | Uneven or temporary land |

| Concrete Piers | Poured concrete columns | Soft or windy areas |

| Concrete Beams | Continuous supports | Permanent installations |

Conduct soil tests and consult an engineer before building to ensure stability.

On-Site Assembly

When modules arrive, builders use laser levels or GPS to position them precisely.

Modules are then bolted or welded together and sealed with weatherproof materials to prevent leaks or air gaps.

A final inspection ensures that electrical, plumbing, and HVAC systems are connected and functional before handover.

Pro Tips for a Smooth Project

Start coordination early: Bring designers, transporters, and inspectors together from the start.

Build a test module: Identify design or fit issues before full-scale production.

Inspect before handover: Check seals, structure, and systems to avoid post-installation issues.

Conclusion

Building and moving a capsule house can be complex—but with the right planning, it’s entirely manageable. Focus on accurate design, proper documentation, and careful transport to ensure your capsule home is safe, efficient, and ready to live in.

❓ FAQ

Q1: How long does it take to build and transport a capsule house?

Usually 8–12 weeks, depending on size and permits.

Q2: Can capsule houses be customized?

Yes. Most manufacturers offer layout and design customization.

Q3: Are capsule homes durable for long-term living?

Absolutely. With treated steel and quality insulation, they can last decades.

Q4: What’s the biggest transport risk?

Improper route planning or poor securing during lifting can cause damage or delays.