Have you ever stood beneath a skyscraper or admired the Eiffel Tower and wondered: How do these massive structures stay secure against storms, earthquakes, and time itself?

The answer lies in more than just steel beams and concrete. It also depends on an unsung hero—the anchor plate. Small but critical, anchor plates are the connectors that keep steel and concrete bonded, ensuring strength and safety for decades.

What is an Anchor Plate?

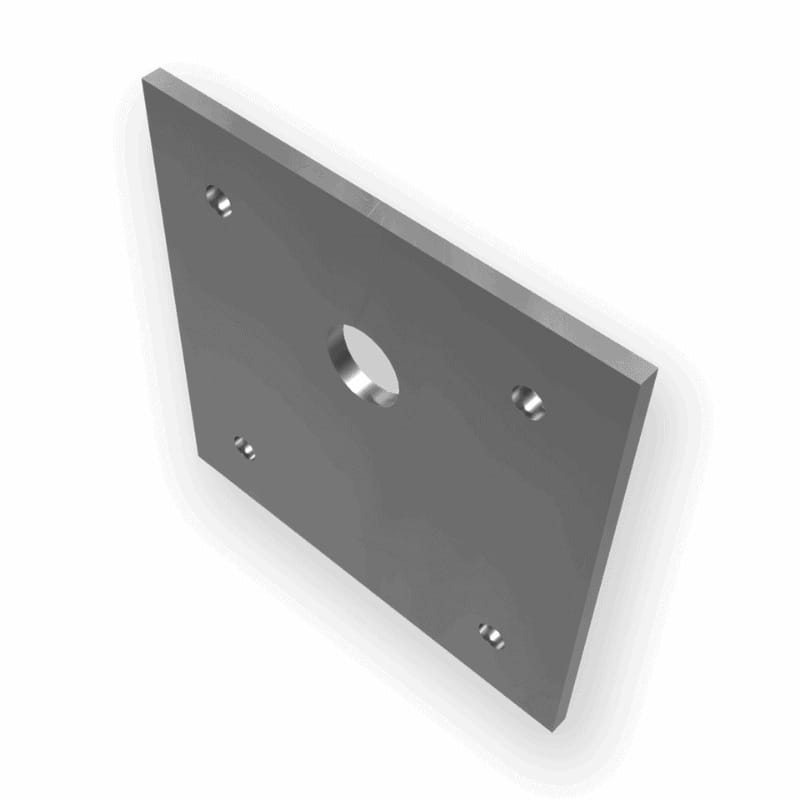

An anchor plate is a flat steel plate—usually square or rectangular—reinforced with bolts, rods, or studs that connect steel structures to concrete foundations.

Think of it as the “joint” of steel construction: small and hidden, but essential.

Key Features of Anchor Plates:

- Shapes: Square, rectangular, L-shaped, or T-shaped

- Functions: Grip concrete and steel firmly

- Reinforcements: Ribs, studs, or bolts for added strength

What is the Purpose of an Anchor Plate?

Anchor plates act as the silent workhorses of structural engineering. Their main roles include:

- Force Transfer – Connect steel and concrete, ensuring vertical and lateral loads are shared.

- Prevent Separation – Resist uplift and shear forces during earthquakes, wind, or heavy loads.

- Load Distribution – Spread concentrated pressure to protect both steel and concrete.

- Accommodate Imperfections – Adjust for minor construction errors with flexible bolt holes.

Base Plate vs. Anchor Plate

These two terms are often confused, but they serve different purposes.

| Aspect | Base Plate | Anchor Plate |

|---|---|---|

| Location | At column base, resting on concrete | Embedded in concrete or between steel members |

| Role | Supports vertical loads (“Don’t sink!”) | Resists uplift & shear (“Don’t detach!”) |

| Forces Tackled | Compression only | Tension, shear, compression |

| Looks Like | Thick solid plate | Perforated with bolts/studs |

Analogy:

- Base Plate = Car suspension (absorbs weight & impact)

- Anchor Plate = Seatbelt buckle (locks and secures under force)

Types & Applications of Anchor Plates

Anchor plates come in different designs, each tailored for specific loads and projects.

| Type | Description | Best Applications |

|---|---|---|

| Flat Plate with Studs | Simple plate with welded studs | Light fixtures, prefab walls |

| L-Shaped / T-Shaped | Angled plates for stronger grip | Beam-to-wall connections, billboards |

| Ribbed Plate | Plate with ridges for pull-out resistance | Earthquake-prone areas, suspended walkways |

Real-World Examples

- Factory Crane Runways: Absorb vibrations and heavy loads from cranes.

- Solar Farms: Anchor steel racks against wind and temperature changes.

- Stadium Roofs: Balance uplift from wind and weight from rainwater.

Anchor Plate Failures & Lessons

When anchor plates fail, the results can be dramatic:

- The Singing Bridge (Spain): Undersized plates caused vibrations in high winds—fixed by switching to ribbed plates.

- Warehouse Collapse (Europe): Missing anchor plates for shelves led to structural failure.

- Stadium Groans (Scandinavia): Polished bolts caused slippage—1,200 plates had to be replaced.

💡 Lesson: Never cut corners. Poor-quality plates = costly repairs.

The Lasting Legacy of Anchor Plates

From skyscrapers to suspension bridges, anchor plates may be hidden, but they are the true guardians of safety. Properly designed and installed, they can outlive the very structures they support.

Fun fact: The Golden Gate Bridge (1937) still uses some of its original anchor plates!

Conclusion

Anchor plates are not just accessories—they’re the backbone of structural stability. Whether you’re building a stadium, a crane runway, or a skyscraper, investing in quality anchor plates ensures safety, durability, and peace of mind.

👉 Your Next Step

- Consult Our Experts: 20+ years of global experience.

- Request a Custom Quote: Tailored anchor solutions for your project.

💬 Final thought:

“Great structures aren’t defined by steel or concrete, but by the connections that hold them together. Choose wisely, build boldly.”