Steel-frame homes differ greatly from concrete or timber buildings in design logic, structural behavior, and durability expectations. Because of this, choosing the right steel material directly determines safety, lifespan, maintenance cost, and construction efficiency.

Below is a clear guide explaining the key material requirements, common steel types, and how to select the best steel for your project.

Key Material Requirements for Steel House Construction

[Image Placeholder — structural steel frame house construction site]

1. Strength & Load-Bearing Capacity

Steel must provide a high strength-to-weight ratio to support walls, floors, and roofs while maintaining stability under wind, snow, and occupancy loads.

2. Corrosion Resistance & Durability

Steel houses often operate in outdoor or semi-exposed environments. Materials should resist rust through galvanization or protective coatings, especially in coastal or humid climates.

3. Flexibility & Ductility

Good ductility allows the structure to absorb external forces such as earthquakes or strong winds, improving structural safety and preventing brittle failure.

4. Easy Fabrication & Assembly

Steel used in modern housing must be easy to cut, weld, and shape. This enables prefabrication and fast modular installation while maintaining precision.

Common Steel Types Used in Steel Houses

[Image Placeholder — comparison chart of different steel materials]

1. Structural Steel

Composition: Low-to-medium carbon steel with manganese and silicon

Benefits

High strength-to-weight ratio

Excellent weldability

Reliable under static and dynamic loads

Applications

Main load-bearing framework — beams, columns, trusses

Common Grades

Q235, Q345, ASTM A36, EN S355

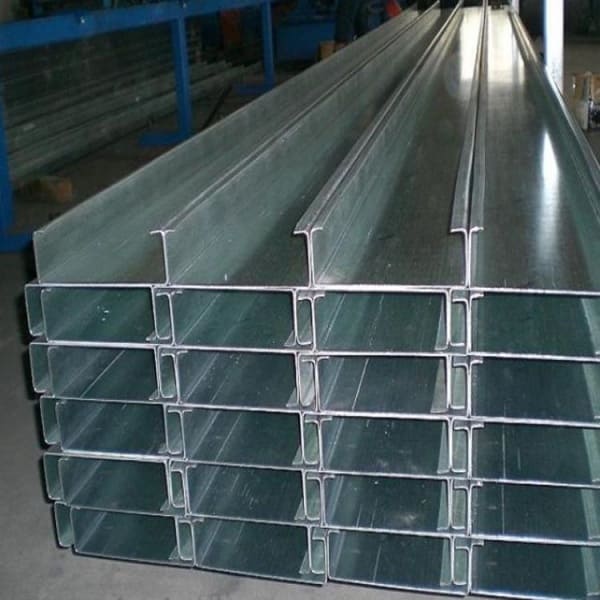

2. Galvanized Steel

Composition: Carbon steel coated with zinc

Benefits

Strong rust resistance

Low maintenance cost

Ideal for outdoor exposure

Applications

Roofing panels, wall cladding, secondary supports

Common Grades

DX51D+Z, SGCC, ASTM A653

3. Mild Steel

Composition: Low carbon content (0.05–0.25%)

Benefits

Easy fabrication

Cost-effective

Flexible applications

Applications

Interior framing, wall supports, decorative components

Common Grades

Q195, Q235, EN S235

4. Weathering Steel

Composition: Alloyed with copper and nickel forming protective oxide layer

Benefits

Self-protecting rust layer

Unique architectural appearance

Minimal maintenance

Applications

Exterior walls, facades, decorative structures

Common Grades

Corten A, Corten B, Q355GNH

5. Stainless Steel

Composition: 10–20% chromium with optional nickel or molybdenum

Benefits

Exceptional corrosion resistance

Modern polished appearance

Long service life

Applications

Railings, window frames, visible architectural elements

Common Grades

304, 316L, 430

6. High Strength Low Alloy Steel (HSLA)

Composition: Carbon steel alloyed with vanadium, titanium, etc.

Benefits

Lightweight but strong

Excellent fatigue resistance

Suitable for large spans

Applications

Multistory homes and wide-span structures

Common Grades

Q460, EN S460, ASTM A572

How to Choose the Best Steel for Your Steel House

Step 1: Understand Structural Requirements

Single-story houses: Q235 or mild steel

Multistory buildings: Q345 or EN S355

Large spans/modular homes: HSLA steel

Step 2: Evaluate Environment

Coastal/humid → Galvanized or stainless steel

Dry inland areas → Structural steel sufficient

Step 3: Balance Budget & Lifecycle Cost

Lower upfront cost → Mild steel

Lower long-term maintenance → Stainless or galvanized steel

Step 4: Match Materials to Components

| Component | Recommended Steel |

|---|---|

| Main frame | Structural steel (Q235/Q345) |

| Roof & walls | Galvanized steel |

| Decorative parts | Stainless steel |

| Large spans | HSLA steel |

Step 5: Verify Quality

Check:

Surface defects

Thickness consistency

ISO/ASTM/EN certifications

Step 6: Work with Reliable Suppliers

Choose suppliers with:

Certified materials

Engineering support

Custom fabrication capability

One-Stop Steel House Solution

Selecting the correct steel can be complex. Professional suppliers can streamline planning, material selection, fabrication, and shipping into one coordinated workflow — reducing cost, delays, and construction risk.

Conclusion

The best steel for a steel house depends on structure, climate, budget, and lifespan expectations rather than a single material choice.

Structural steel provides the backbone

Galvanized steel protects exposed areas

Stainless steel enhances durability and appearance

HSLA steel enables large and lightweight structures

By combining the right steel types and grades, a steel house becomes safer, longer-lasting, and more cost-efficient over time.