Finding the right suppliers for prefab homes can make or break your business.

Reliable partners ensure consistent quality, on-time delivery, and smooth operations.

In this guide, you’ll learn how to identify, evaluate, and manage trustworthy suppliers for your prefab housing projects.

1. Understand What You Need

Before contacting any supplier, list exactly what materials and components you need.

Common prefab components include:

| Category | Examples | Notes |

|---|---|---|

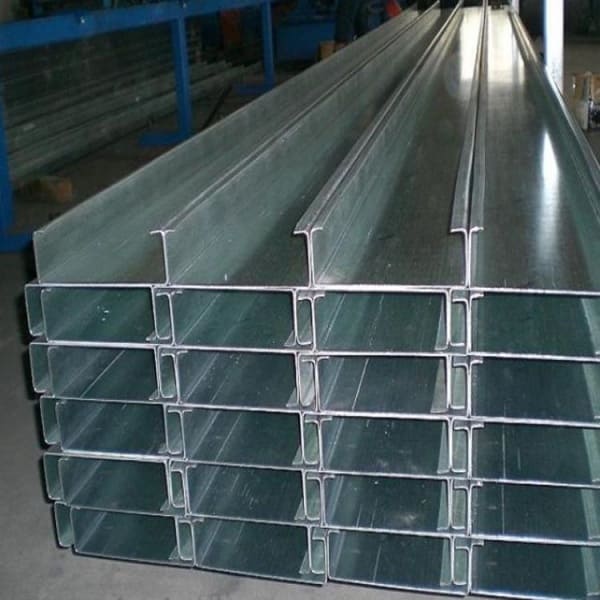

| Structural Frame | Steel beams, aluminum panels | Key for durability and strength |

| Wall & Roof Panels | Insulated sandwich panels, EPS boards | Affects insulation and comfort |

| Windows & Doors | Aluminum or PVC systems | Should meet thermal and sound standards |

| Plumbing & Electrical | Pipes, wiring, fixtures | Must comply with building codes |

| Interior Finishes | Flooring, cabinetry, lighting | Impacts design quality and aesthetics |

Knowing your material list helps you target specialized suppliers instead of general traders.

2. Research and Shortlist Potential Vendors

Start your search using multiple sources:

Industry trade directories (e.g., Alibaba, Global Sources, Made-in-China).

Prefab housing expos and trade fairs — great for face-to-face discussions.

Referrals from industry peers — often the most trustworthy leads.

Online reviews and certifications on supplier websites.

Shortlist at least 3–5 suppliers for each major component to compare quality, price, and response time.

3. Verify Supplier Credentials

Once you have your shortlist, confirm each supplier’s legitimacy.

Ask for business licenses, ISO certifications, or factory audit reports.

Check if they’ve worked with international buyers before.

Request client references or photos of completed prefab projects.

Confirm their export experience if you plan to ship overseas.

A reliable supplier will be transparent and ready to share proof of experience.

4. Evaluate Product Quality

Quality control is the foundation of your prefab business.

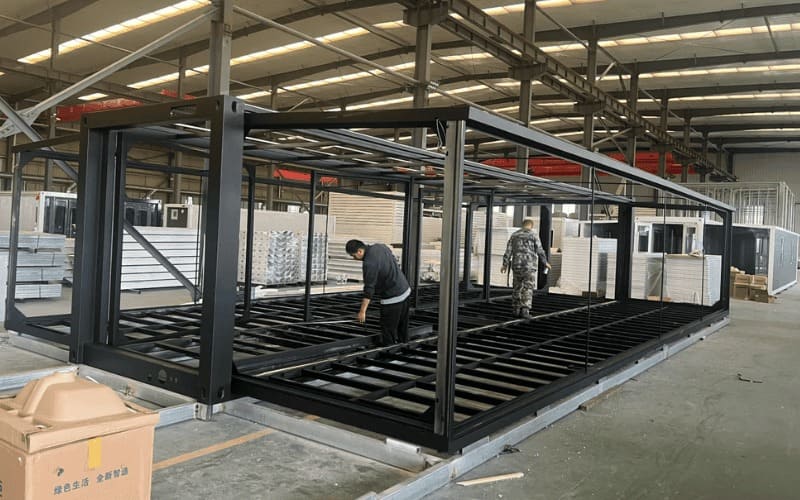

Request product samples or visit the factory to inspect materials.

Ask about quality standards (e.g., CE, ASTM, or local equivalents).

Inquire about testing procedures for structural strength and insulation.

Check the packaging and labeling system to ensure safe shipping.

If an on-site visit isn’t possible, hire a third-party inspection agency for independent verification.

5. Compare Prices and Delivery Terms

Once quality is confirmed, evaluate the commercial terms carefully.

| Criteria | What to Look For |

|---|---|

| Pricing Transparency | Avoid vague or hidden costs |

| Minimum Order Quantity (MOQ) | Ensure it fits your production scale |

| Lead Time | Check production and delivery timelines |

| Payment Terms | Prefer milestones over full upfront payment |

| After-Sales Support | Ensure warranty and replacement options |

Don’t just choose the cheapest option — look for value, reliability, and communication.

6. Test with a Pilot Order

Before committing to long-term cooperation, place a small test order.

This allows you to evaluate real-world factors such as:

Communication speed and clarity

Packaging quality during transport

Material accuracy versus samples

Responsiveness in solving issues

A smooth pilot order builds confidence for future large-scale cooperation.

7. Build Long-Term Relationships

Strong supplier relationships create long-term business success.

Communicate clearly and consistently about production schedules.

Share feedback after each project.

Offer long-term contracts to reward reliable partners.

Visit suppliers regularly to maintain trust.

A good supplier becomes part of your value chain — not just a vendor.

8. Use Technology to Manage Your Supply Chain

Modern prefab companies use digital tools to stay organized.

Implement ERP systems to track materials and orders.

Use cloud-based documentation for easy access and updates.

Automate quality checklists and delivery tracking.

Technology reduces human error and strengthens supplier collaboration.

✅ Summary

Choosing reliable prefab suppliers is about more than price — it’s about trust, consistency, and shared standards.

By researching, testing, and maintaining transparent relationships, you can ensure that every prefab home you deliver meets the highest quality expectations.

❓ FAQ

1. How can I check if a prefab supplier is legitimate?

Ask for licenses, certifications, and past project references. Trusted suppliers are always transparent.

2. Should I visit the factory before ordering?

Yes, if possible. Factory visits help verify equipment, materials, and production capacity.

3. What’s the safest payment method for new suppliers?

Use milestone payments or secure trade platforms with buyer protection.

4. How can I manage multiple suppliers effectively?

Use ERP tools or project management software to track quality, delivery, and communication.