Imagine the Eiffel Tower swaying in the wind or the Sydney Opera House resisting seismic waves. These icons don’t just rely on steel’s strength—they depend on hidden joints, like shear plates, that transfer forces seamlessly.

A shear plate may look simple, but it is one of the most reliable force distributors in steel construction—keeping beams, columns, and floors connected under stress.

Essential Concepts Beforehand

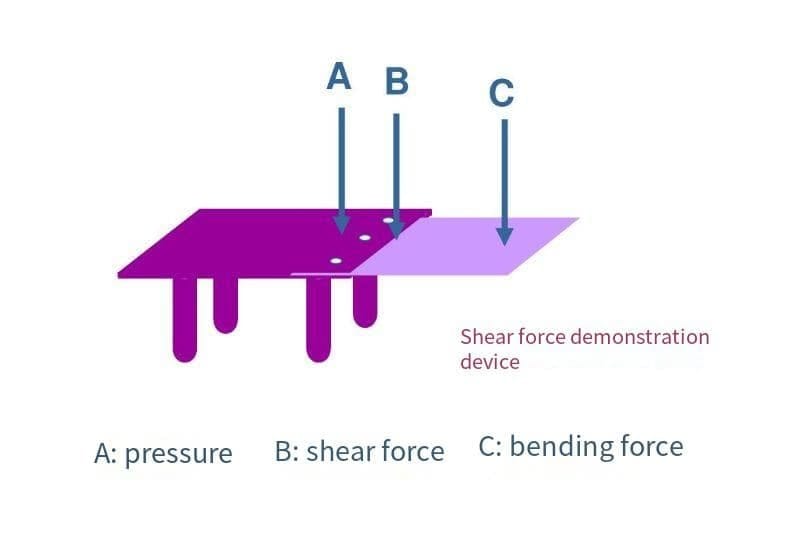

Before diving into shear plates, here are three basics:

- Shear Force – Like scissors cutting paper, shear is a sideways force that pushes one layer to slide over another.

- Examples: wind on skyscrapers, earthquakes shaking bridges, or heavy machinery vibrations.

- Shear Connection – Think of Lego blocks. A shear connection lets members lock together horizontally without slipping, balancing strength + flexibility.

- Yield Strength (Fy) – The stress level where steel stops springing back and starts deforming. Shear plates are designed to work below Fy, ensuring safety.

What is a Shear Plate?

A shear plate is a flat rectangular steel plate with bolt holes, usually welded or bolted at beam-column intersections.

Key Features:

- Material: Grade 50 steel (Fy = 50 ksi)

- Thickness: 12–25 mm

- Placement: Hidden in joints, often fireproofed

- Size Example: About as big as an A3 sheet, yet strong enough to anchor a bus!

Why Use Shear Plates?

Without shear plates, welded joints may crack under seismic or wind loads. Plates offer:

- Stress Distribution – Spread forces like snowshoes on snow.

- Controlled Deformation – Bolted joints flex slightly, absorbing shocks.

- Modularity – Prefab plates speed up assembly.

📊 Test Insight (SCI 2023):

Connections with shear plates resisted 30% higher lateral loads than welded joints.

How Shear Plates Work

Step-by-step:

- Clamp Force: Bolts tighten the plate to members, creating friction.

- Force Redistribution: Load spreads evenly through bolts and plate.

- Fail-Safe Mode: If friction slips, bolts act in bearing mode, preventing collapse.

💡 Pro tip: Anti-slip coatings (like grit blasting) boost capacity by 20%.

The Golden Formula: Shear Capacity

The formula engineers use:

V = 0.6 × Fy × A

- V: Shear capacity

- Fy: Yield strength

- A: Effective area (plate minus bolt holes)

| Example | Value |

|---|---|

| Steel Grade | 50 ksi |

| Plate Thickness | 0.5 in |

| Effective Width | 6 in |

| A = t × w | 3 in² |

| V = 0.6 × 50 × 3 | 90 kips (≈ 400 kN) |

🎯 Translation: Enough to lift 9 SUVs!

Shear Plates in Shear Connections

A shear plate works with:

- High-Strength Bolts – Apply clamp force

- Anti-Slip Coatings – Increase friction

- End Plates – Bridge beam to plate

- Stiffeners – Prevent buckling

Shear Plate vs. Shear Key vs. Anchor Plate

| Feature | Shear Plate | Shear Key | Anchor Plate |

|---|---|---|---|

| Material | Steel | Concrete | Steel |

| Force Type | Shear in steel | Shear in concrete | Uplift & tension |

| Location | Beam-column joints | Foundations, dams | Column bases |

| Failure Mode | Bolt shear / buckling | Concrete cracking | Pullout / cone breakout |

Why Shear Plates Are Revolutionizing Construction

- Modular Speed: Prefab, bolt-on design cuts erection time by 40%.

- Sustainability: Less waste, reusable connections, optimized steel.

- Seismic Resilience: Bolts dissipate energy safely; 80% less damage seen in retrofits.

- Cost Efficiency: Lower labor + fewer welding errors = savings.

Conclusion

Shear plates are silent guardians that:

- Spread shear forces

- Prevent brittle failures

- Support modular, sustainable, and seismic-safe construction

They are the unsung heroes holding skyscrapers, bridges, and factories together.

Easter Egg: Notre-Dame’s Medieval “Shear Plates”

In Notre-Dame Cathedral, medieval builders used iron cramps—primitive friction grips similar to shear plates.

When inspected after the 2019 fire, many were still intact after 800 years.

Proof that force distribution is timeless engineering wisdom.