Struggling with slow builds, high costs, and shaky durability? Steel structures flip the script—delivering unmatched strength, rapid assembly, and eco-friendly vibes that transform factories, stadiums, and more into engineering wonders.

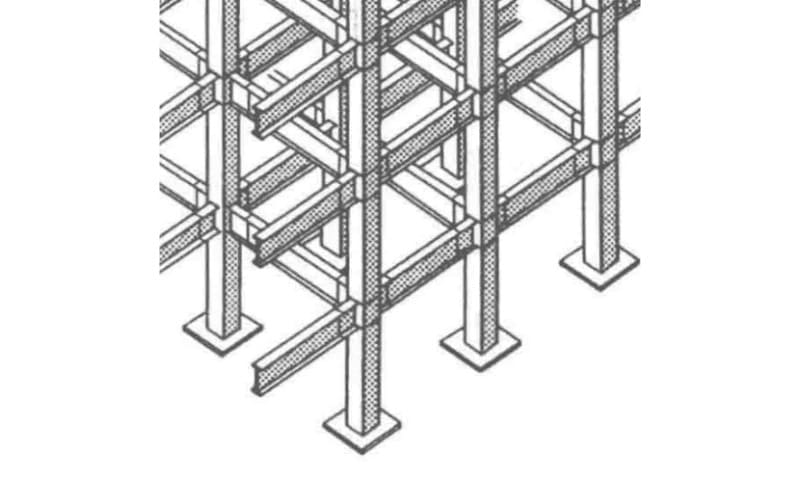

Steel structures shine through their core components: columns for vertical support, beams for horizontal spans, trusses for efficient load transfer, plus robust floors, roofs, walls, and foundations. Together, they ensure stability against loads, wind, and quakes while enabling flexible, column-free designs for versatile spaces.

Ever wondered how these powerhouse parts sync up to create buildings that last? Stick around as we dissect the essentials, revealing insider tips to elevate your next project from good to groundbreaking.

What Forms the Backbone of Steel Structures?

Tired of flimsy frames that buckle under pressure? The primary structural framework steps in as the unyielding hero, shielding your build from collapse and chaos.

It comprises columns, beams, and trusses that bear vertical and lateral loads, resist wind and seismic forces, and maintain overall stability—forming a resilient skeleton for any steel edifice.

Diving deeper, this framework isn’t just steel stacked high; it’s a symphony of engineering precision. Columns anchor the load vertically, beams span horizontally for open layouts, and trusses optimize for vast, unobstructed areas. Critically, their interplay prevents failure modes like buckling or shear—think of it as a load-balancing act where each element anticipates the others’ limits.

Steel Columns: The Vertical Powerhouses

- Role: Transfer roof, floor, and live loads to foundations.

- Key Challenge: Handling eccentric loads in asymmetrical designs.

Steel Beams: Horizontal Load Lifters

- Role: Support slabs and define spatial flow.

- Key Challenge: Managing deflection over long spans.

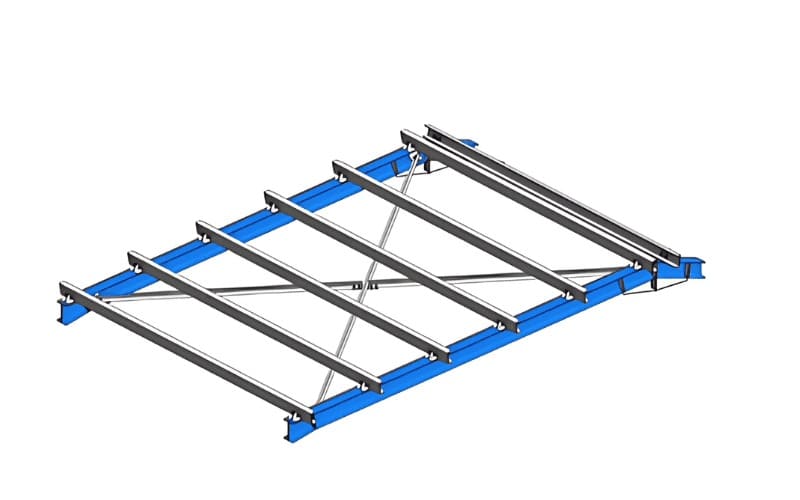

Trusses: Efficient Span Masters

- Role: Enable column-free roofs and bridges via triangular geometry.

- Key Challenge: Joint integrity under dynamic winds.

| Component | Load Type | Common Shapes | Pro Tip |

|---|---|---|---|

| Columns | Axial/Eccentric | H-shaped, CHS | Use base plates for seismic damping. |

| Beams | Bending/Shear | I-beams, Box | Opt for continuous spans to cut material by 20%. |

| Trusses | Tension/Compression | Planar/Space | Bolted gussets speed fab by 30%. |

This setup not only slashes material use but boosts sustainability—fewer resources mean a greener footprint.

How Do Steel Columns Keep High-Rises Standing Tall?

Fearing your tower might sway like a reed in the wind? Steel columns crush that nightmare, locking in vertical might to support skyscraping ambitions without a wobble.

As primary vertical bearers, steel columns handle thousands of tons from roofs and floors, channeling them to foundations while countering lateral threats like earthquakes for unshakeable stability.

Beyond basics, columns demand smart selection to match site specifics—circular for aesthetics in public icons, H-shaped for raw industrial grit. Critically, eccentric loading in quirky designs risks twisting; counter it with bracing. Types vary by need, but all prioritize corrosion resistance via galvanizing.

Types of Steel Columns

- Cross-Section Shapes: Circular for wind resistance; square for modular fits.

- Load Types: Axial for uniform weights; eccentric for offset forces.

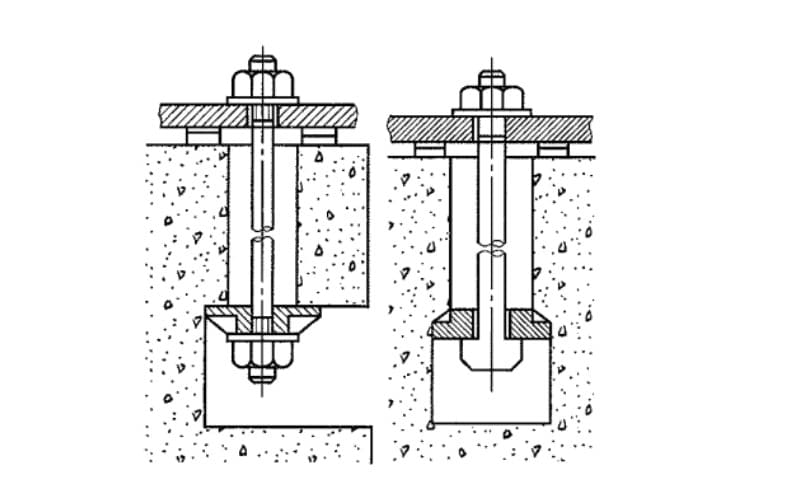

Connection Methods

- Bolted: Quick swaps in temp builds.

- Welded: Ironclad for permanence.

- Base Plates: Anchor to footings seamlessly.

| Type | Use Case | Advantage | Limitation |

|---|---|---|---|

| Axially Loaded | Warehouses | Even distribution | Less flexible for offsets |

| Eccentrically Loaded | Asymmetrical towers | Handles imbalances | Needs extra bracing |

| Tubular (CHS) | Bridges | Aesthetic + aero-efficient | Costlier fab |

Integrating these ensures 50+ year lifespans, slashing retrofit costs.

Why Are Steel Beams the Unsung Heroes of Open Spaces?

Overwhelmed by cramped layouts and sagging floors? Steel beams bulldoze barriers, crafting vast, versatile interiors that breathe life into your vision.

They span floors and roofs, bearing slabs, occupants, and snow while dictating room flows—transferring loads to columns for safe, sound structures that adapt to any design.

Peel back the layers: Beams aren’t generic; I-beams excel in pure bending, channels hug walls efficiently. Cantilevers push boundaries for balconies, but watch for end-moment spikes—continuous designs distribute better, cutting steel by 15%. Connections seal the deal, with welds for rigidity in quakes.

Types of Steel Beams

- Cross-Section Shapes: I for depth; box for torsion.

- Load Characteristics: Simply supported for basics; continuous for efficiency.

Connection Methods

- Bolted: Field-friendly adjustments.

- Welded: Max shear transfer.

- Shear Plates: Boost joint toughness.

| Shape | Span Suitability | Load Capacity | Design Hack |

|---|---|---|---|

| I-Beam | Medium (10-30m) | High bending | Camber for deflection control |

| H-Beam | Long (20-50m) | Heavy duty | Hybrid with composites for vibes |

| Cantilever | Overhangs | Projection pro | Balance with counterweights |

This intel empowers cost-savvy choices, turning specs into savings.

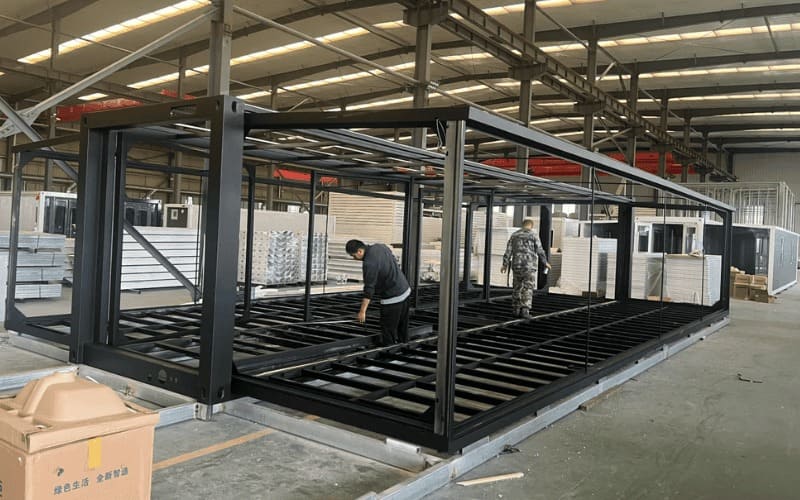

What Powers the Floors and Roofs in Steel Builds?

Dreading soggy leaks or bouncy decks? Floor and roof systems in steel setups deliver ironclad platforms that shrug off elements and loads alike.

Decking and composite slabs form tough floors via steel-concrete bonds for heavy-duty support; roof panels and purlins shield with insulation and load paths, ensuring watertight, energy-smart performance.

Unpack the duo: Floors lean on decking’s quick-pour base, composites amp stiffness via shear studs—fireproof bonus curbs insurance hikes. Roofs? Panels lock out rain with seams, purlins space for even stress, joints flex for temp swings. Critically, mismatch them, and you invite cracks; align for 40% faster pours.

Floor Systems

- Decking: Permanent formwork, light yet tough.

- Composite Slabs: Steel-concrete synergy for spans.

Roof Systems

- Panels: Insulated sandwiches for efficiency.

- Purlins: C/Z sections optimize distribution.

- Expansion Joints: Climate-tuned flex zones.

| System | Key Benefit | Install Time | Eco Edge |

|---|---|---|---|

| Composite Slab | Fire-resistant strength | 2x faster than cast-in | Recycles 70% steel |

| Profiled Decking | Versatile for walls too | Day-per-floor | Low embodied carbon |

| Roof Purlins | Prevents hot spots | Bolt-on ease | Lightweight cuts transport |

Master these, and your build hums with longevity.

How Do Walls and Foundations Seal the Steel Deal?

Anxious about drafts, shifts, or storms breaching your build? Walls and foundations fortify the envelope, turning steel skeletons into storm-proof sanctuaries.

Wall panels insulate and enclose against elements; girts and beams stabilize facades; foundations with anchor bolts ground loads evenly, preventing settlement for total structural harmony. (30 words)

Delve in: Walls sandwich insulation for R-values that slash HVAC bills 25%, girts grid for wind defiance. Foundations? Bolts bite deep, plates spread stress—ignore soil tests, and hello, tilts. Beams in walls beef up for multi-stories, connections weld for quake-proof.

Wall Systems

- Panels: Sound/water barriers.

- Girts/Beams: Load relays.

Foundation Elements

- Column Bases: Even distribution.

- Anchor Bolts: Anti-lift locks.

| Element | Function | Material Tip | Risk Mitigation |

|---|---|---|---|

| Wall Panels | Thermal shield | PU foam core | Seal joints yearly |

| Anchor Bolts | Uplift resist | Galvanized | Torque to spec |

| Wall Girts | Panel anchor | Cold-formed Z | Space per wind code |

These lock in efficiency, future-proofing your investment.

Conclusion

Steel structures thrive on synergistic components—from frameworks to foundations—delivering durable, adaptable builds that conquer loads and elements with ease.

Choose wisely for smarter construction.