Struggling with unstable garages that shift or sink? Ignoring footings leads to costly repairs and safety hazards.

Yes, most steel garages need footings for stability, distributing weight to prevent settling. They anchor the structure against soil shifts, ensuring longevity—essential in poor soils or heavy loads.

Don’t let foundation doubts halt your project; dive deeper to build with confidence.

What Are Footings?

Confused about what holds your garage steady? Skipping basics risks uneven settling and structural failure.

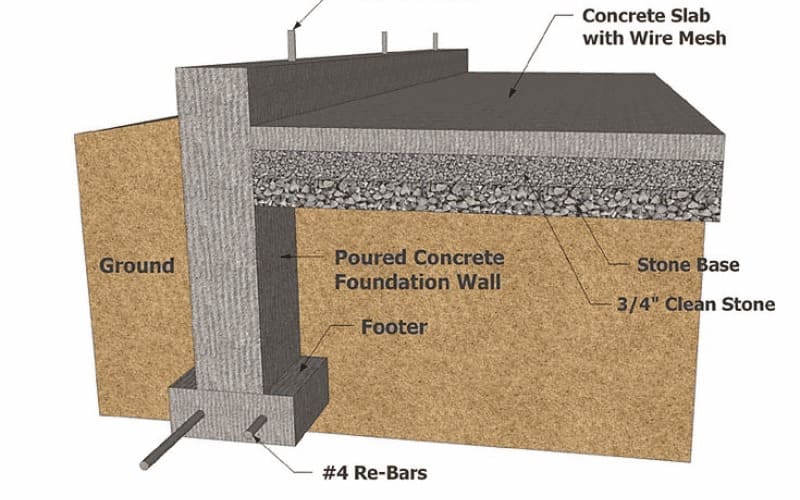

Footings are concrete bases buried underground, spreading the garage’s weight for stability and preventing sinking or shifting, tailored to soil and conditions.

Footing vs. Foundation: Key Differences

Footings form the bottom layer, directly contacting soil to bear loads, while foundations include walls or slabs above them. Critically, footings prevent differential settlement by distributing forces evenly.

Why Footings Matter in Steel Structures

Steel garages exert point loads via columns; without proper footings, soil compression leads to cracks. Analyze soil bearing capacity first—use tests to determine if reinforced concrete is needed.

| Aspect | Footing Role | Foundation Role |

|---|---|---|

| Depth | Buried below frost line | Extends upward from footing |

| Material | Primarily concrete with rebar | Includes blocks or poured walls |

| Purpose | Load distribution to soil | Overall structural support |

This breakdown highlights how footings anchor against environmental stresses, ensuring your investment lasts.

Do I Need Footings for My Steel Garage? Why?

Worried your garage might collapse without support? Neglecting footings in unstable areas invites disaster and violations.

Yes, footings are crucial for larger garages, poor soils, or code compliance, distributing weight to avoid shifting and ensuring safety.

Reasons Footings Are Essential

Break down by factors: For heavy loads, footings prevent uneven settling; in soft soils, they stabilize against moisture-induced shifts; codes mandate them in freeze-prone or seismic zones.

Debunking Common Misconceptions

Many think small garages skip footings—wrong! Even minor structures risk tilting, leading to repairs. Critically evaluate: Test soil, consult codes, and reinforce for longevity.

| Factor | Why Footings Needed | Potential Risks Without |

|---|---|---|

| Size/Weight | Distributes heavy loads | Uneven settling, cracks |

| Soil Conditions | Anchors in unstable ground | Shifting, sinking |

| Building Codes | Ensures compliance | Fines, structural failure |

This analysis empowers informed decisions, protecting your garage from foreseeable issues.

How Do Soil and Environmental Conditions Impact Footing Design?

Facing unpredictable ground that threatens your build? Poor conditions amplify risks of heave and instability.

Soil type and climate dictate footing depth and size; unstable soils need deeper designs, while frost-prone areas require below-frost-line placement for stability.

Unstable Soil Impacts and Solutions

Soft or sandy soils reduce bearing capacity, risking tilt. Solutions: Deepen to 18-24 inches, enlarge areas with strip footings, or stabilize via compaction and piles.

Frozen Ground (Frost Heave) Challenges

In cold regions, freezing expands soil, lifting structures. Counter: Bury below 36-inch frost line, add rebar/heating, and ensure drainage to mitigate water accumulation.

| Condition | Impact | Design Adjustment |

|---|---|---|

| Unstable Soil | Low bearing, settling | Deeper/wider footings, stabilization |

| Frozen Ground | Heave from expansion | Below frost line, drainage systems |

Critically, assess via soil tests to tailor designs, preventing environmental-driven failures.

What Types of Footings Are Best for Steel Garages?

Overwhelmed by footing options for your garage? Choosing wrong leads to inefficiency and added costs.

Common types include strip for walls, isolated for columns, slab-on-grade for level ground, and deep for unstable soil, selected by garage size and site.

Breaking Down Footing Types

Strip footings support linear loads cost-effectively; isolated handle point columns in large builds; slab-on-grade spreads evenly on stable sites; deep penetrate for firm soil layers.

Matching Types to Project Needs

Critique: For seismic areas, prefer reinforced isolated; in flat, stable zones, slab suffices. Always factor load and soil—mismatches cause cracks.

| Type | Best For | Pros | Cons |

|---|---|---|---|

| Strip | Long walls | Cost-effective, even distribution | Less flexible for points |

| Isolated | Columns | Targeted support | Requires precise placement |

| Slab-on-Grade | Level ground | Simple, full base | Not for unstable soil |

| Deep | Soft soil | Reaches stable layers | Higher cost, excavation |

This structured approach aids in selecting optimal footings for durability.

What Are the Key Requirements for Steel Garage Footings?

Unsure if your footings meet standards? Weak specs invite cracks and compliance issues.

Requirements include 12-inch minimum depth, steel reinforcement, 2500+ psi concrete, frost-proofing, and proper drainage for stability and longevity.

Essential Specifications

Depth and size vary by load/soil; reinforcement prevents cracking; concrete strength ensures load-bearing; freeze-proofing buries below frost line; drainage slopes water away.

Critical Compliance Factors

Analyze: In cold climates, deepen for heave; test concrete psi. Neglect leads to erosion—integrate rebar/mesh for tensile strength.

| Requirement | Details | Purpose |

|---|---|---|

| Size/Depth | 12+ inches, wider for loads | Stability against settling |

| Reinforcement | Rebar/mesh | Crack prevention |

| Concrete Strength | 2500-4000 psi | Weight support |

| Freeze-Proofing | Below frost line | Heave resistance |

| Drainage | Slope away, pipes | Water damage avoidance |

This breakdown ensures footings withstand time and elements.

How Should I Plan Footings for My Steel Garage?

Stressed about footing planning pitfalls? Poor prep delays projects and inflates budgets.

Plan by consulting pros, assessing soil, sizing for loads, checking codes, and budgeting for excavation/materials to ensure a stable build.

Step-by-Step Planning Process

Consult engineers for design; test soil for type/stability; calculate garage load for footing specs; review local codes for depth/seismic needs; allocate budget/timeline for digs and pours.

Avoiding Common Planning Errors

Critically: Skip soil tests? Risk instability. Underbudget? Face overruns. Integrate pros early for compliance and efficiency.

| Step | Action | Benefit |

|---|---|---|

| Consult Professional | Engineer/contractor input | Customized, code-compliant design |

| Assess Soil | Tests for conditions | Tailored footing type/depth |

| Determine Size/Load | Calculate garage needs | Adequate support |

| Understand Codes | Local regs review | Legal safety |

| Budget/Timeline | Factor costs/delays | Smooth execution |

This methodical plan safeguards your investment.

Conclusion

In summary, steel garages typically require footings for stability against settling, influenced by size, soil, and codes.

From understanding basics to selecting types and planning meticulously, proper footings ensure longevity. Assess your site, consult experts, and build confidently to protect your structure for years.